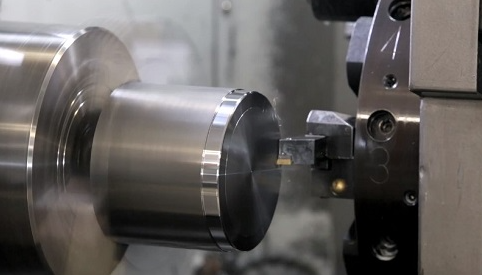

Sonke sihlangabezane nenkinga yokuxoxa kwendawo yokusebenza ngesikhathi sokujika kwe-CNC.Ingxoxo elula idinga ukusetshenzwa kabusha, futhi ingxoxo enzima isho ukuchithwa.Kungakhathaliseki ukuthi iphathwa kanjani, iwukulahlekelwa.Indlela yokuqeda ingxoxo endaweni yokusebenza yeUkuphenduka kwe-CNC?

Ungayiqeda Kanjani Ingxoxo & Ukudlidliza Kokusebenza Okungaphezulu Ekujikeni kwe-CNC

Ukuze kuqedwe ingxoxo yendawo yokusebenza ekuguquleni kwe-CNC, sidinga ukwazi imbangela yengxoxo.

1. Izinkinga zomshini

Kunezimbangela ezimbili ezingenzeka zethuluzi lomshini.

(1) Uma i-workpiece iboshwe ngekhava ephezulu, isandiso se-jacking side kakhulu, okuholela ekuqineni okwanele.

(2) Umshini ngokwawo usetshenziswe isikhathi eside, ukunakekelwa akukafiki ngesikhathi, futhi ama-bearings angaphakathi nezinye izingxenye zigugile kakhulu.

2. Amathuluzi

Kunezizathu ezine ezingenzeka zethuluzi lomshini.

(1) Ithuluzi elisele linwebeka isikhathi eside kakhulu ngesikhathi sokujika, okuholela ekuqineni okunganele.

(2) I-blade igugile futhi ayibukhali.

(3) Ukukhethwa kwamapharamitha wethuluzi lomshini ngesikhathi sokuphenduka akunangqondo.

(4) I-tip arc yeblade inkulu kakhulu.

3. Izinkinga Zokusebenza

Kunezimbangela ezintathu ezingaba yizimbangela zezinto zokwenziwa.

(1) Izinto zokuguqula umsebenzi ziqine kakhulu, ezithinta ukuphenduka.

(2) I-workpiece ephendukayo yinde kakhulu, futhi i-workpiece ayiqinile ngokwanele ngesikhathi sokujika.

(3) Izinto ezisebenza odongeni ezizacile aziqinile ngokwanele lapho uphendula iziyingi.

Uma ukuzamazama kwenzeka ngesikhathi sokuphenduka, indlela yokuqeda inkinga?

1. Umsebenzi

Okokuqala, hlola ukuthi ingabe kukhona inkinga nge-workpiece.

(1) Uma i-workpiece impahla okufanele iguqulwe inzima kakhulu, ungashintsha inqubo ukuze unciphise ubulukhuni be-workpiece, bese uyithuthukisa ngezinye izindlela kamuva.

(2) Uma ucezu lokusebenzela okufanele luguqulwe lude kakhulu, landela umnikazi wethuluzi ukuze uthuthukise ukuzinza kwe-workpiece.

(3) Uma i-workpiece inezindonga ezincane, i-tooling ingaklanywa ukuthuthukisa ukuqina lapho uphendulela i-excircle.

2. Amathuluzi

Okulandelayo, ake sibone ukuthi ingabe kuyinkinga yethuluzi.

(1) Uma ukuphumula kwethuluzi kunwebeka isikhathi eside, hlola ukuthi indawo yokuphumula kwethuluzi ephansi ingalungiswa yini.Uma kungenjalo, buyisela indawo yokuphumula yethuluzi ngensimbi ephakeme.Uma kunesidingo, sebenzisa ithuluzi lokuphumula le-anti vibration.

(2) Uma i-blade igugile, shintsha i-blade.

(3) Uma isizathu siwukuthi imingcele ekhethiwe yomshini ayinangqondo, shintsha uhlelo bese ukhetha imingcele enengqondo.

(4) I-arc yethiphu yethuluzi inkulu kakhulu, futhi i-blade idinga ukushintshwa.

3. Ithuluzi lomshini

Okokugcina, yahlulela ukuthi ingabe kunenkinga ngethuluzi lomshini nokuthi ithiphu lethuluzi elingafanele liyasetshenziswa

(1) Uma kusetshenziswe okungaphezulu okungafanele, okungaphezulu okunokusebenza okuhle kudinga ukushintshwa.

(2) Uma ithuluzi lomshini ngokwalo lisetshenziselwa isikhathi eside kakhulu futhi ukugcinwa kungafiki ngesikhathi, kuyadingeka ukuthintana nabasebenzi bokulungisa ithuluzi lomshini ukulungisa ithuluzi lomshini.

Kuthiwani Uma Ingekho Inkinga Itholakala?

Uma singazitholi izinkinga ezisekelwe kula maphuzu angenhla, yini enye esingayenza?Kungase kusekelwe ocwaningweni kumgomo wokudlidliza wokusetha ithuluzi.Njengamanje, kunezindlela ezithile eziqondile nezisebenzayo ezisetshenziswa endaweni yokucubungula:

(1) Yehlisa isisindo sokusebenza sezingxenye ezibangela ukudlidliza, futhi i-inertia encane iba ngcono.

(2) Nge-eccentric workpiece, yenza amathuluzi ahambisanayo.

(3) Lungisa noma qinisa izingxenye ngokudlidliza okukhulu kakhulu, njengohlaka olumaphakathi, ikheji yokusebenza, njll.

(4) Khulisa ukuqina kwesistimu yokucubungula, isibonelo, sebenzisa isibambi sethuluzi esine-coefficient ephezulu yokunwebeka noma sebenzisa amandla akhethekile okulwa nokudlidliza ahlanganiswe ne-damper eguquguqukayo ukuze umunce amandla omthelela.

(5) Ngokombono we-blade ne-workpiece yokuzungezisa isiqondiso.

(6) Shintsha ukuma kwethuluzi kanye ne-angle yokuphakelayo, i-radius yethiphu encane iba ngcono, futhi unciphise ukumelana nokusika.I-engeli yokuthambekela esemaceleni kufanele ibe iphozithivu ukwenza isiqondiso sokusika sisondele kokume mpo.I-engeli ye-caster ingcono ukuthi ibe iphozithivu, kodwa noma ngabe ikhono lokususwa kwe-chip liphansi, ngokuvamile lingasetshenziswa ukwenza i-engeli ye-caster ibe negethivu, kodwa igcine inani elihle lomthelela wokusika.

Isikhathi sokuthumela: Oct-22-2022