I-Teknic ingumholi womhlaba kwezokusakaza, enamakhasimende asukela ezinkampanini ezinkulu ezikhiqiza izinto zikagesi kuya embonini yezimoto kusukela kumqondo wokuklama, kuya ekukhiqizeni nasekupakisheni.

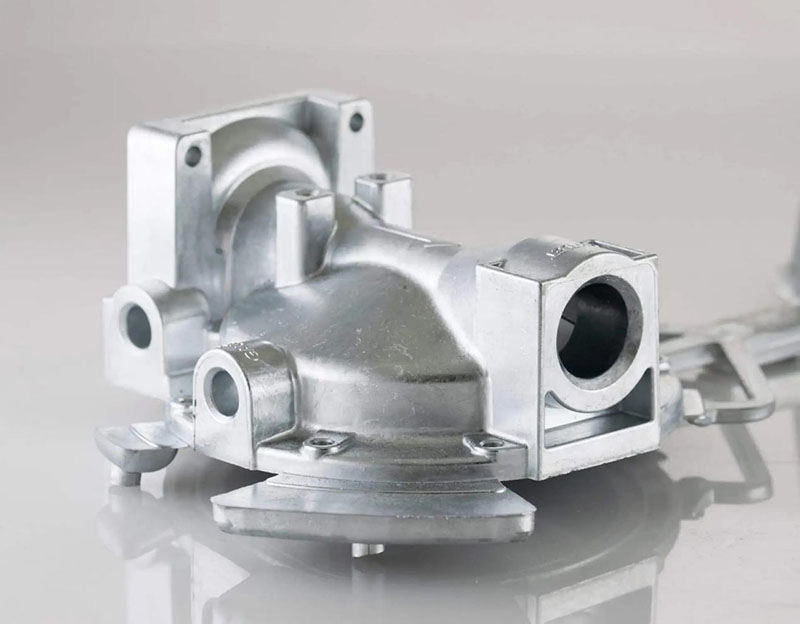

Sihlinzeka nge-zinc die casting kusukela ekuklanyweni nasekuhlolweni kwesikhunta, kuya ekukhiqizeni ingxenye ye-zinc, ukuqedela, nokupakisha kusukela ekucacisweni kwedizayini eyinkimbinkimbi futhi sikuguqule kube umkhiqizo oqediwe.

I-Teknic ihamba phambili ezinkampanini ezikhipha i-zinc die eminyakeni eyi-10.Selokhu yasungulwa, siguqukele ekubeni umholi osezingeni lomhlaba sisebenzisa ochwepheshe bayo nabanekhono ukwenza ama-die castings asezingeni eliphezulu.Sigxile kwikhwalithi nokuxazulula izinkinga e-China.isekelwe endaweni yokukhiqiza i-Zinc Molding.

Izimo Eziyinkimbinkimbi & Ukubekezelelana Okuqinile

I-Zinc die casting ikhiqiza i-multi-cavity, izimo eziyinkimbinkimbi futhi ngaphakathi kokubekezelelana okuseduze kunezinye izinqubo eziningi zokukhiqiza.Ngokungeziwe ekukhiqizeni ukugijima kwevolumu ephezulu ezingxenyeni ezicishe zifane, ikhiqiza ukushisa okumazombezombe futhi igqoke izingxenye ezimelana nokuqina, kuyilapho igcina ukubekezelelana okusondele kakhulu.

Inqubo ye-die casting inika abaklami ithuba lokonga izindleko ngokuhlanganisa izingxenye zibe yi-net-shape die casting eyodwa.Ngakho-ke, okunamandla okuqeda imisebenzi yesibili njengomshini.Ama-Zinc die castings aklanywe ngempumelelo njengama-bearings (okuqeda ama-alloys ethusi), ama-rivets, futhi angaba nentambo.Ngenxa yalezi zinzuzo, ama-die castings atholakala ezinhlobonhlobo zezimboni ezihlanganisa ezezimoto, i-hardware yokwakha, i-electronics, impahla yezemidlalo, njll.

Kufanele kuqashelwe ukuthi ukubekezelelwa kwezinga lemboni kungahlangatshezwana nazo futhi/noma kudlule, uma kudingekile ekwakhiweni kwengxenye.Nokho-ke ziningi izinto okumele zibhekwe njenge;umumo wengxenye, lapho isici sitholakala ngaphakathi kwethuluzi, siyini indawo yaso nezinye izici zengxenye futhi uma ulinganisa ngaphesheya komugqa wokuhlukanisa.Uma kucutshungulwa impilo yamathuluzi nezindleko, kuwumkhuba ongcono kakhulu ukuvumela ukubekezelelana okuphanayo kanye nokusalungiswa ezindaweni ezinokulingana okuncane, isimo noma umsebenzi kanye nokuqinisa ukubekezelelana kuphela ezindaweni lapho kudingekile khona.

I-Zine die Casting yethu ihluka ngosayizi ukusuka kumathani ayi-100 kuye kwangama-300, ikhiqiza izingxenye ze-zinc die casting ezinhlelweni zokukhiqiza umthamo ophansi noma ophezulu.Singenza i-zinc hot chamber die casting, i-aluminium-zinc eshisayo noma ebandayo ye-high pressure die casting, kanye ne-aluminium die casting.Ukuqapha inqubo, ukuthwebula isithombe esiseceleni, amarobhothi, ukulingisa ukugeleza, amathuluzi angapheli kanye nezinhlelo zokulungisa amathuluzi zisetshenziselwa ukunweba impilo yamathuluzi, ukonga izindleko, isikhathi, nokuhlinzeka ngekhwalithi ephezulu yokulingisa.Ukusuka ekukhulelweni okuyingxenye kanye ne-prototyping ephelele, ukuya ekuhlanganiseni umkhiqizo oqediwe.

I-Zinc Alloys

Singumholi ekukhiqizeni i-die casting e-China.Ochwepheshe bethu be-Metallurgists abaqeqeshiwe baqinisekisa ukuthi wonke ama-alloys ahlangabezana nokucaciswa ngokuqhubekayo ngokuhlaziywa kwamakhemikhali nokomzimba.

Ama-alloys ethu afaka:

Zinc: Zamak 3, 5, and 7.

I-Zinc-Aluminium: ZA-8, ZA-12, ne-ZA-27.

Ama-alloys e-Zinc ayindlela elula yokucindezela okuphezulu.Banikeza i-ductility ephezulu, amandla omthelela, futhi angafakwa kalula.Ama-alloys e-Zinc anephuzu eliphansi lokuncibilika kune-aluminium engasiza ekuthuthukiseni impilo yokufa.

Ama-alloys e-ZA ayizinto zokuphonsa ezisekelwe ku-zinc ezinokuqukethwe okuphezulu kwe-aluminium kune-alloys evamile ye-zinc.Lawa ma-alloys anezici zamandla aphezulu futhi nokuqina okuphezulu kanye nezakhiwo ezithwala kahle.

Ukuhlolwa kokugeleza kwe-Zinc Mold

I-Teknic isebenzisa ubuchwepheshe bokulingisa be-CAM obaziwa umhlaba wonke ukuze kuthuthukiswe idizayini yamathuluzi kanye nekhwalithi yokulingisa i-zinc.

Amandla wokulingisa we-CAM anikeza ukuqonda okungcono kokugcwalisa isikhunta somjovo we-zinc, ukuqina, izakhiwo zemishini, ukucindezeleka okushisayo nokuhlanekezela.Eqhutshwa imenyu ngokugcwele ngemodeli eqinile edidiyelwe, izixhumanisi ze-CASD, kanye nedathabhesi ebanzi, i-CAM inikeza isisombululo esiphelele sokuklama, ukukhiqiza, kanye neminyango yekhwalithi.

Steel Umjovo Mold Castings

CNC Machining kanye Hog-outs

I-Direct Metal Laser Sintering (DMLS)

P-20 Amathuluzi

I-ZINC SURFACE FINISHING

I-Teknic izophatha izimfuneko zokuqeda ikhasimende ukuze iqinisekise ukuthi izingxenye zihlangabezana nokucaciswa kwazo kokubili ngesikhathi nangendlela engabizi kakhulu.

Ukuqedwa kwe-zinc surface yethu kuhlanganisa:

I-Powder Coating (uhlelo lokusebenza lwe-electrostatic)

Upende Omanzi

I-Chromate

I-E-Coat

I-Electroless Nickel

I-Chrome

Ukuhlola Usilika kanye Nestencing

I-EMI/RFI Shielding

I-Surface Conditioning (ukudubula nokuqhunyiswa kobuhlalu)